Joint Commission Readiness - How Can We Make Utility System Testing Consistent and Survey-Ready?

Our latest post kicks off the follow-up series to last summer’s webinar, “Be Audit-Ready Every Day: Automate Your Joint Commission Prep with Improv.” Many of the attendees asked for a deeper dive into the most common questions from that session, so we’re starting with one of the highest-risk — and most misunderstood — areas: Utility System Testing.

Hospitals rely on emergency generators, transfer switches, and backup lighting to protect patients when the power goes out. These systems only save lives if they’re tested routinely, documented consistently, and repaired quickly when issues appear. Joint Commission surveyors know this, which is why emergency power testing is one of the most scrutinized elements during surveys.

This article breaks down:

What utility system testing really means and the cadence hospitals must follow

Why it’s central to Joint Commission readiness and where surveyors typically find gaps

What surveyors examine in your logs—from weekly EPSS inspections to 36-month load tests

How optimized, automated processes reduce risk for leaders and make life easier for Facilities and Biomed staff

How process intelligence strengthens compliance, improves accountability, and eliminates test drift

What is Utility System Testing?

Utility system testing refers to the routine inspection and testing of a hospital’s emergency power and lighting systems to ensure they will perform when the power grid fails. This typically includes testing your Emergency Power Supply Systems (EPSS) including backup generators, automatic transfer switches (ATS), and battery-powered emergency lights on a set cadence. These tests, and the logs they generate, are the proof that your hospital can keep patients safe during power outages.

A disciplined testing program catches weak components early and ensures true readiness when it matters most. In short, utility system testing is about proactively verifying all critical power systems so that no one is left in the dark during an emergency.

An example cadence:

Weekly EPSS generator inspection

Monthly: generator cold-start under load ≥30 minutes meeting ≥30% nameplate or manufacturer exhaust temp, plus ATS testing

Annual: emergency lighting 90-minute test; supplemental load bank if monthly never meets load/temp; manufacturer-recommended ATS maintenance.

36-month: Level 1 EPSS 4-hour test (combining rules allowed).

Why Does Utility System Testing Matter for Joint Commission Readiness?

Power failures in a hospital can be life-threatening, so it’s no surprise that emergency power system testing is a hot spot in Joint Commission surveys. Surveyors pay close attention to generator and lighting test records because missed tests, incomplete logs, or unclear ownership of testing tasks will trigger surveyors.

A hospital could have top-tier generators, but if you can’t show consistent documentation and immediate follow-up on any issues, you risk being cited for non-compliance. In contrast, a tight testing schedule with clear documentation and prompt corrective actions is often the difference between being compliant versus being caught unprepared.

In essence, utility system testing matters because it directly reflects your hospital’s culture of safety and reliability – areas the Joint Commission scrutinizes to ensure patients, staff, and visitors are protected at all times.

What do Joint Commission Surveyors Look for in Utility System Testing?

Joint Commission surveyors will ask to see evidence that all required emergency power system tests are being performed on schedule and according to standards. Specifically, surveyors review proof of:

Weekly inspections of the Emergency Power Supply System (EPSS): This includes the generator and all associated components (fuel systems, batteries, radiators, etc.) up to and including each ATS. They want to see that someone visually checks the generator and its support systems every week, with any issues noted and addressed.

Monthly generator load tests: Generators must be “cold-started” and run under load for at least 30 continuous minutes each month. The test should achieve at least 30% of the generator’s nameplate kW rating (or meet the manufacturer’s recommended exhaust temperature.) During this test, each automatic transfer switch should also be tested by transferring the facility’s load to the generator and back. Surveyors will check that these 12 monthly tests were done at intervals not exceeding 30 days (with a grace period up to 10 days, so never more than 40 days apart.)

Monthly emergency lighting tests: Battery-powered emergency lights (for exits, egress routes, task lighting, etc.) must be tested every 30 days for at least 30 seconds. Surveyors look for logs of these functional light tests (often just a push-button test) and that any bulb or battery issues were fixed promptly.

Annual 90-minute lighting test: Once a year, those same emergency lights must undergo a 90-minute full discharge test to ensure batteries can sustain emergency illumination. All results and completion dates should be documented.

Triennial 4-hour full load test: For hospitals with Level 1 emergency generators, a 4-hour continuous run test is required at least every 36 months. This is often done with a supplemental load bank if monthly tests never hit the 30% load threshold. Surveyors will ask to see the report from your last 36-month (4-hour) generator test.

Follow-up on failures: If any required test failed or any equipment didn’t meet criteria, there must be evidence of corrective action and a re-test after repairs. For example, if a generator didn’t start or an exit light failed the 90-minute test, surveyors expect to see a work order, a repair or battery replacement, and a passing re-test documented. Simply finding problems is not enough – you must show they were fixed.

In summary, surveyors are essentially validating compliance with Joint Commission standard EC.02.05.07, which mandates scheduled testing and maintenance of emergency power systems. They will verify that your records cover all the intervals (weekly, monthly, annual, 3-year) and include details like dates, personnel, results, and any code references or manufacturer guidelines followed. Being prepared with organized, complete logs (with signatures, readings, and timestamps) for at least the past 12 months is key to acing this part of a survey.

What Do Optimized Utility System Testing Processes Solve for Leaders?

For hospital leaders and facilities managers, optimized utility testing means fewer surprises, tighter compliance, and greater visibility. Modernizing how tests are scheduled, performed, and tracked solves several common pain points:

No more test drift: Monthly generator and ATS tests stay within the required 30-day cadence thanks to automated reminders and deadline tracking (and escalation.) This prevents missed windows and last-minute scrambles.

Proactive alerts: The system flags missed tests or abnormal results in real time. Leaders can address issues before surveyors arrive, with each test showing results and documented follow-up.

Standardized documentation: Digital workflows enforce complete test records—load %, duration, transfer times, and deficiencies. Reports meet Joint Commission expectations without extra effort.

Clear accountability: Named owners for each test eliminate confusion between Facilities and Biomed. Everyone sees who’s responsible and when.

Enterprise-wide oversight: A single dashboard displays testing status and trends across locations. Leaders can prioritize repairs or coaching where needed.

Lower compliance risk: With reliable cadence, prompt repairs, and audit-ready logs, survey citations become rare—and emergency power readiness becomes real.

An optimized process aligns testing with TJC standards, replacing fire drills and paperwork with a predictable, survey-proof routine.

How Do Optimized Utility System Testing Processes Help Staff?

Facilities, Biomed, and engineering staff benefit directly from streamlined testing processes that reduce friction and support their work.

Step-by-step guidance: Digital checklists walk techs through each test, prompting for cold starts, readings, transfer times, and required evidence.

Less logging and duplication: Staff enter data once, during the test—no clipboards, spreadsheets, or retyping later.

Instant handoffs for failures: If a generator won’t start or a light fails, the system auto-creates a CMMS ticket with ownership and due dates. No chasing or follow-up required.

Alerts where they work: Teams or Slack notifications replace scattered emails. Summary reports keep everyone informed of status and outstanding issues.

Fast record access: During tracers, staff can pull up 12 months of test history in seconds, by asset and date, with no binders or system-hopping.

Better onboarding and morale: Clear processes help new hires ramp up quickly. When issues are fixed based on what techs report, it builds trust and ownership.

When the system supports the people doing the work, utility testing runs smoother—and no one dreads Joint Commission week.

Build an Effective Utility System Testing Program with Process Intelligence

A reliable emergency power testing program doesn't rely on memory or spreadsheets. It’s built on clear strategy, structured workflows, automation, and intelligent support. Here’s how Process Intelligence simplifies compliance:

Strategy (Clarity and Alignment First)

Define the cadence and scope: Set test frequencies for generators, ATS, and emergency lights based on Joint Commission and NFPA standards (e.g., EC.02.05.07). Example: generator monthly load tests, ATS monthly tests, emergency lights monthly + annual.

Assign clear roles: Map who is responsible for each test or fix. Use a simple RACI chart to eliminate confusion.

Document the plan: Update your Utility Systems management policy so everyone understands expectations.

Workflow Design (Standardize the Test)

Step-by-step checklists: Use structured digital workflows to guide staff through each test, capturing required readings and photos. See a few sample Process Street checklist steps below.

Required fields and logic: Force completeness with mandatory data and hide irrelevant tasks using conditional prompts.

QR asset check-in: Scan equipment codes to launch the correct checklist instantly.

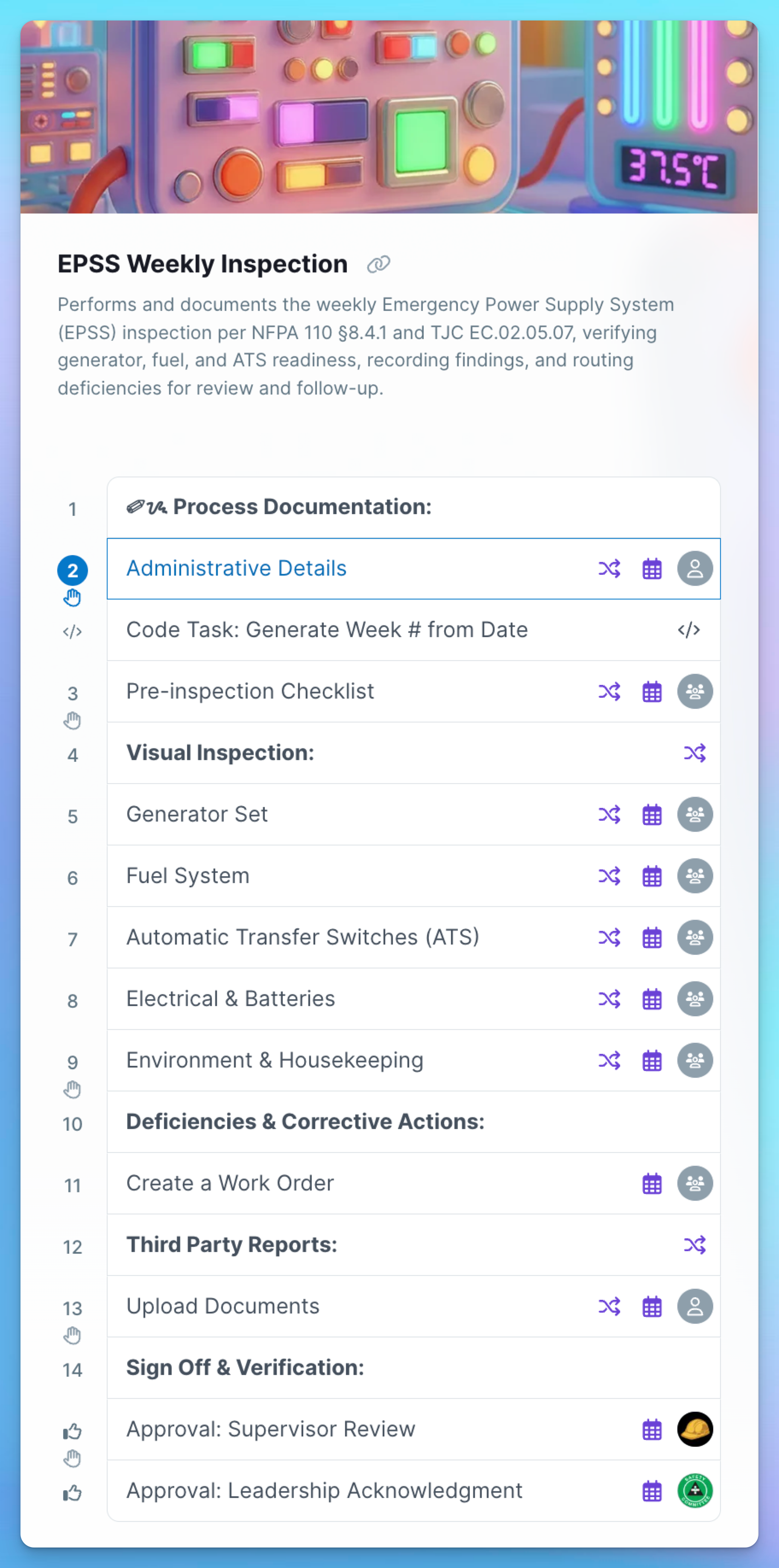

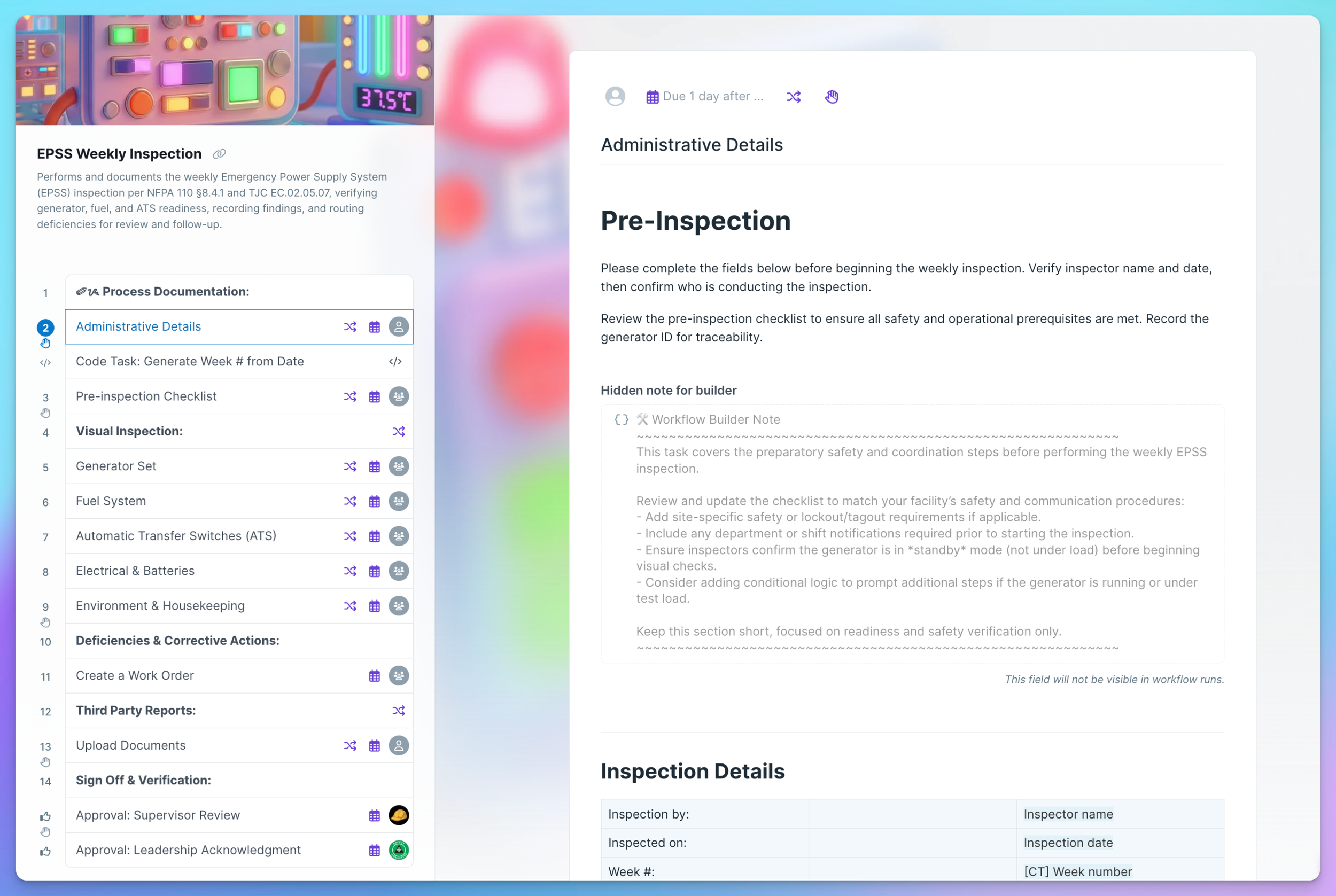

EPSS Weekly Inspection Checklist

EPSS Weekly Inspection Checklist & Builder View of Admin Details – Screenshot

EPSS Weekly Inspection Checklist Conditional Logic

Automation (Keep Everyone on Track)

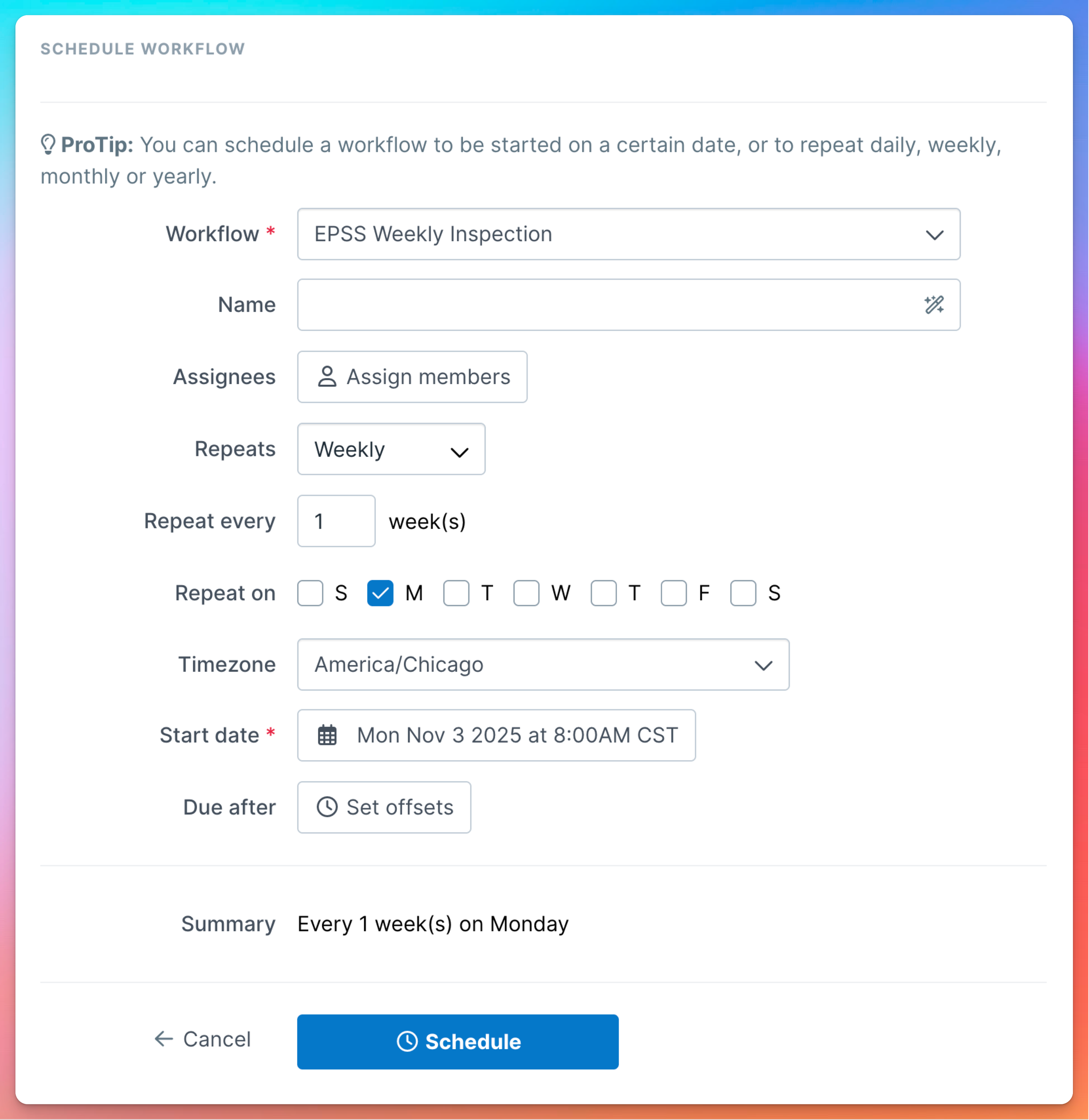

Scheduled checklist generation: Workflows can run on a schedule easily maintained and updated by the leadership team.

Auto-alerts and nudges: Remind owners when test windows open or deadlines are near. Notify leaders if a test is missed.

Work order generation: Failed tests automatically open tickets and track resolution.

Sync across systems: Post test status updates to Teams/Slack and link back to work orders.

EPSS Weekly Inspection Workflow Schedule

EPSS Weekly Inspection Work Order Creation – Screenshot

Digital Assistants (AI Help Where Work Happens)

Instant answers: Ask, "Which ATS missed a test?" or "Show generator test failures this quarter."

Auto-reports: Copilot drafts readiness summaries and tracer narratives from recent activity.

Guided support: Staff get real-time help, fewer mistakes, and faster retrieval during survey tracers.

Metrics That Matter

Track what counts: Percent of tests completed on time, repeat failures, time to fix issues, and transfer time outliers.

Use the data: Spot patterns, shorten repair times, and justify upgrades with evidence.

With Process Intelligence, emergency power testing becomes a predictable, closed-loop system: clear for staff, visible to leaders, and built to withstand survey scrutiny.

How to Implement and Automate Utility System Testing Processes

You don’t need to overhaul overnight. Follow these practical steps to launch a better testing program:

Inventory assets: List all generators, ATS, and emergency lights, with test frequency and last-test date.

Build workflows: Use Process Street to create recurring checklists with required fields, photo capture, and pass/fail logic.

Connect systems: Auto-create work orders on failed tests and push updates to Slack/Teams.

Pilot first: Start in one building. Check QR use, photo quality, and if alerts and tickets work as expected.

Train and launch: Run quick trainings, install QR codes, and shift to the new system.

Track exceptions: Use weekly reports to spot delays or repeat issues early.

Review metrics: Monitor test completion rates and repair times to drive improvement.

Proof to Keep for Your Joint Commission Surveyor

Surveyors expect fast, credible proof of compliance. Keeping this package ready is easy because your PI system already holds it all and understands what the surveyor will likely ask for:

12 months of test logs: For each generator, ATS, and emergency light – with dates, results, readings, and who performed them.

Fix evidence: Show linked work orders and closure notes for any test failures.

Policy and roles: Your EOC plan or testing policy, showing test schedule and owner assignments.

Training records: Proof staff are qualified to perform tests.

System of record: One searchable place (like Process Street) that holds logs, photos, signatures, and linked CMMS tickets.

With this data organized and accessible, you won’t fumble when surveyors ask, “Show me your generator testing history.” You’ll just pull it up on your phone or iPad and show them.

Bottom line on Joint Commission Readiness for Utility Systems

Ready to simplify emergency power compliance? Our Process Intelligence team will build a unified testing workflow for generators, ATS, and lighting, automate alerts and work orders/tickets, and enable real-time readiness. Check us out at Process Services | Improv.

Request a 30-minute working demo — we’ll load your asset list and show your emergency power data in action.

References

TJC — Emergency Power Systems (Standards FAQs): monthly generator & ATS testing expectations; emergency lighting 30-sec monthly and 90-min annual. Joint Commission+2Joint Commission+2

TJC — Weekly EPSS inspection scope (EC.02.05.07 EP4): components to inspect and documentation. Joint Commission

TJC — 4-hour/36-month guidance & combining with annual: load profiles when combining tests (NFPA 110). Joint Commission+1

NFPA 110 (2010/2016) summaries: monthly ≥30 minutes, ≥30% nameplate or exhaust temp; 36-month test. Joint Commission+1

CMS K918 (Essential Electric Systems): 10-second capability; annual verification if not shown in monthly testing. ClearPol App Storage

ATS test initiation/transfer simulation: use ATS test switch/opening breaker to simulate outage (state LSC guidance citing NFPA 110 8.4.3). MN Department of Health